Form follows Function

The next step is "form follows function".

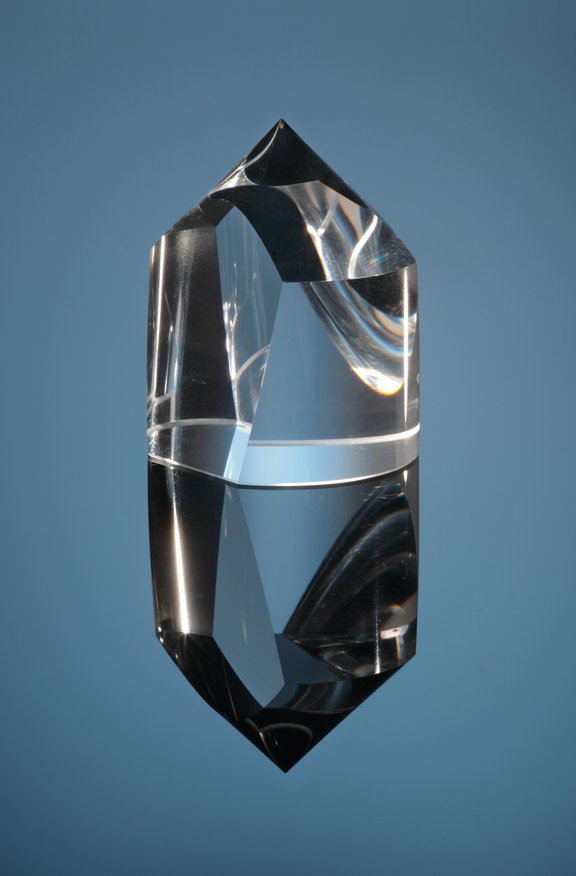

With the most modern computer-controlled machines and a large stock of tools, which can be produced quickly and specifically by us thanks to CAD technology, the sawing, grinding and polishing process begins.

Depending on the quality requirements and complexity, the finishing touches are added at the end – a great deal of sensitivity and experience is required for the fine sanding in our polishing workshops, because it is also and especially important here to have a precise knowledge of the different material properties.

Specific documentation and controls according to your specifications or current quality standards round off the development process.

Start of serial production

If the prototype fulfills your vision, we start the development of serial production.

Many of our current customers have walked this challenging path with us, and together we continue to crank up the momentum.

We love this challenge, because it allows us to keep up with the times and guarantee you the highest quality in all our products at all times.