Let’s start with visions: having a clear idea of what you are trying to achieve is always the first step in any development process. This is true for every project, whether we are manufacturing optical components for you or working on our own company’s development. Our aim is to keep pace with the constant technological advances being made in our industry and to ensure we manufacture products of the highest quality. To this end we measure the quality of our products using every method at our disposal. We start by documenting every detail and every stage of the workflow for each product and we conclude the process when the product has successfully completed all post-production tests.

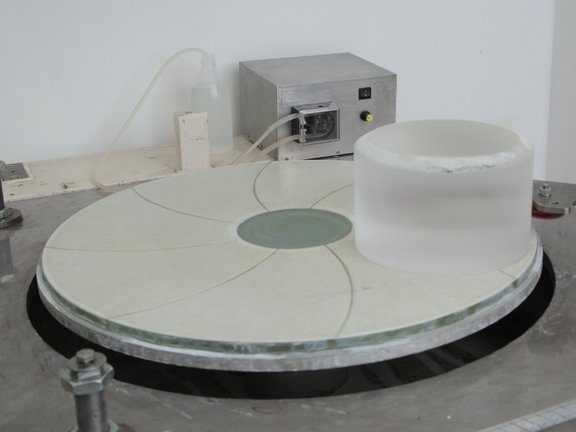

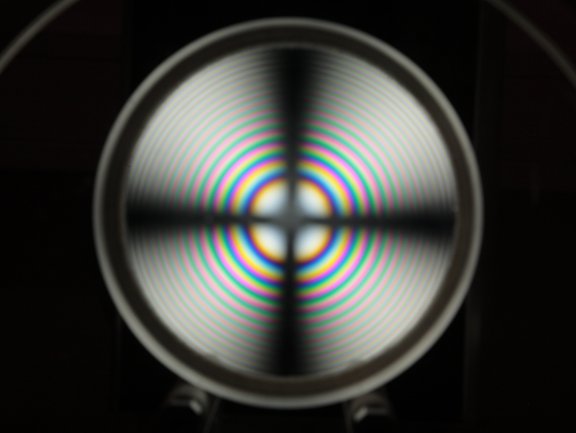

As experts with many years’ experience, however, we also know enough tricks of the trade to verify the quality of our blanks before the final automated controls. With materials such as Magnesium Fluoride, for example, which is birefringent, we conduct a visual test, (amongst others), to check its orientation. This is where the “cross hairs” come in – if the material is oriented correctly, cross hairs will be visible with regular shaft rings.

This visual inspection allows us to determine the best use for the blank, before it goes into processing.